Efficiency

Prahova Plant Pushes Envelope of Technological Advancement

In this era of rapid innovation in power transmission systems and shifting trends in mobility and transportation, Timken’s tapered roller bearing (TRB) remains essential to any equipment designer who wishes to roll a load.

When the company decided to build a new tapered roller bearing plant in 2015, those technological considerations came into play, as well as geographical ones. The Timken Company originated in North America, naturally offering bearings in imperial units. As it expanded across the world in the 1920s, the company broadened its offering to include metric sizes.

“We focused this new Romanian plant on the metric products that are used throughout Europe,” says Doug Smith, vice president of technology. European designers are creating a wide array of products that require 100-300 millimeter-sized tapered roller bearings for the markets Timken serves, including agriculture, construction and mining. The new plant helps meet growing aftermarket demand from Timken distributors in the region.

“Timken is known for its high-quality, high-performance products, but we’re also known for our high-touch technical service model,” says Smith. Having supply chains and manufacturing plants in the regions where original equipment manufacturer (OEM) customers operate is essential to providing the level of service they expect from Timken.

The next level of modern manufacturing

Timken began manufacturing bearings in Romania in 1997, when it acquired a plant near Ploiesti. There, the company produces large bore bearing solutions for industrial markets. “Geographically, we’re nestled right in the midst of all the markets that we want to reach out and touch,” says Smith.

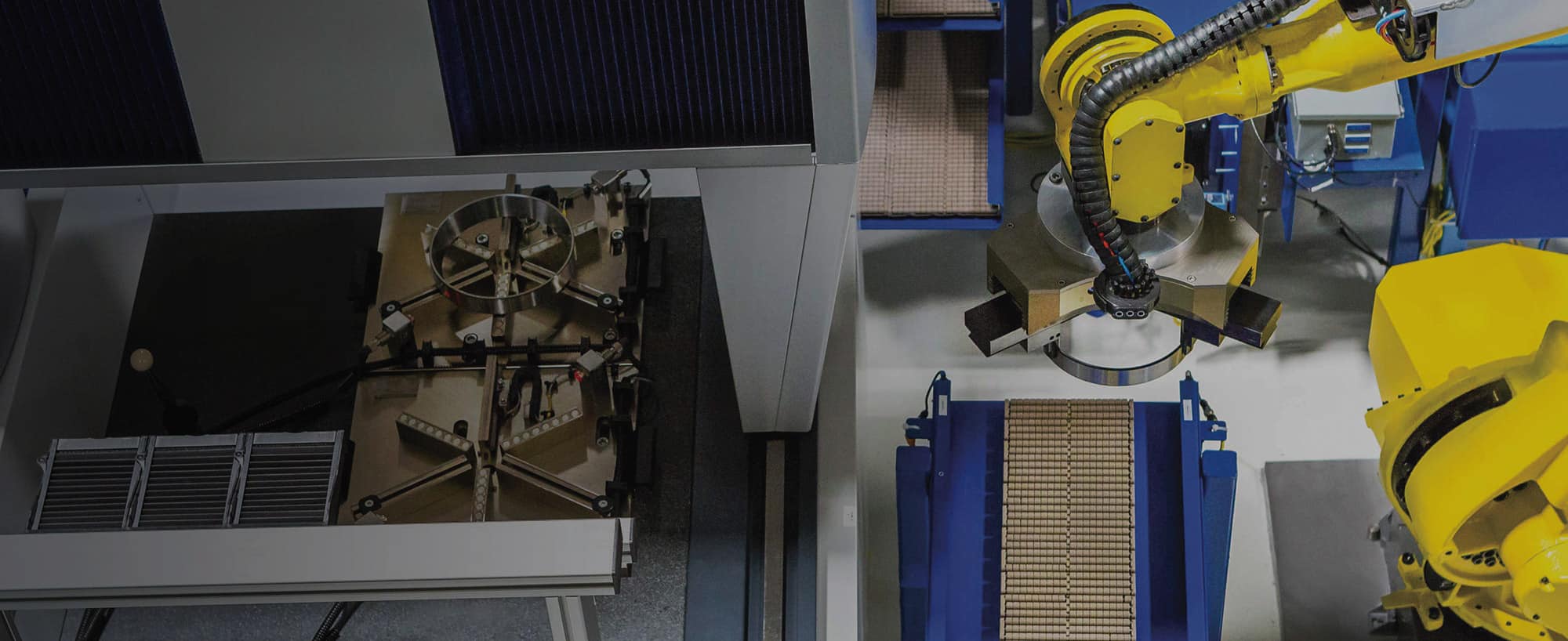

The new Prahova plant, just 20 kilometers away from Ploiesti, features sophisticated advancements in computer controls, robotics and automation. “We’ve taken our game to the next level, from the perspective of modern manufacturing,” says Smith.

While Prahova associates demonstrate a new level of technical savvy and engineering acumen, Timken’s basic operating methodologies have not changed. “Prahova is equipped to handle a wide variety and volume of part numbers quickly and efficiently,” says Smith. “Our improved operating model and state-of-the-art technologies help with that.”

Making Timken quality more accessible

Timken’s investment in the Prahova plant represents a significant step forward in the thermal treatment and finishing processes that have always played a central role in Timken product performance. The advanced through-hardening processes and furnace technologies rolled out at Prahova improve consistency through the heat-treating process, yielding significant downstream productivity improvements.

Those technologies and processes help Timken sustain its status as the world’s leading manufacturer of tapered roller bearings. “Our partners value consistency and reliability above all else. Head-to-head trials have shown that our tapered roller bearing can outlast the competition,” says Smith.

That performance comes as a result of three Timken differentiators: material specifications, thermal treatments and finishing processes. “You can layer on top of that the quality systems and inspection techniques that we use throughout the process and supply chains, which is how we make sure we get exactly what we engineer,” says Smith.

As companies in Asia increasingly look to Europe as a center for product design, the Prahova plant makes it easy for Asian customers to incorporate Timken’s manufacturing leadership as they work on next-generation designs. “It gives them better access,” says Smith. “We can be there from the beginning of the design process, to show them the plant and to interact with the team.”

Timken’s new Prahova plant features sophisticated advancements in computer controls, robotics and automation.

120 years of raising standards

Since the company’s founding in 1899, Timken has dramatically expanded its product lines, but the tapered roller bearing remains a bedrock for customers around the world, even as design requirements evolve dramatically.

Even after 120 years, the world’s greatest tapered roller bearing remains on the cutting edge of advances in materials science and manufacturing capabilities. Doug Smith, vice president of technology, talks about how Timken is unleashing the power that leadership to expand the product portfolio.

“Many of these new scenarios require a more power-dense, fuel-efficient, or economical tapered roller bearing,” says Smith. “That’s something we can make very capably at Prahova.” Using the thermal treatment capabilities and finishing technologies available there, he says, “we can make extremely power-dense products that pack a lot of punch into a small volume envelope.”

Smith looks forward to building on Prahova’s successes. “We challenged ourselves to think differently as we developed and deployed new technologies in this plant. It’s effectively the new standard for our operating model in this class of products,” he says.

“We’ve always stood for quality, dependability, and performance, and we accepted nothing less when we were designing this facility and the products that we would make there,” says Smith. “It’s a continuation of Timken’s performance legacy, and it’s already proven itself an asset for key customers.”

Last Updated: 2021/08/19

Published: 2019/01/15