The Challenge

Bucket elevators, a vital part of the production process in cement plants, carry heavy loads under arduous conditions. One customer experienced challenges in replacing components that keep these heavy-duty workhorses running. In its operations, buckets attached by two chains carry crushed limestone 40 yards to the top of a pre-heater tower, with the shaft itself supporting up to 16 tons of weight. When the drive-side head pulley bearing failed, it would take three working days to remove and replace it, since it was trapped between the bucket elevator drive pulley and the gearbox/motor assembly. The maintenance costs: Three days of lost production time and the expense of renting a 35-ton crane.

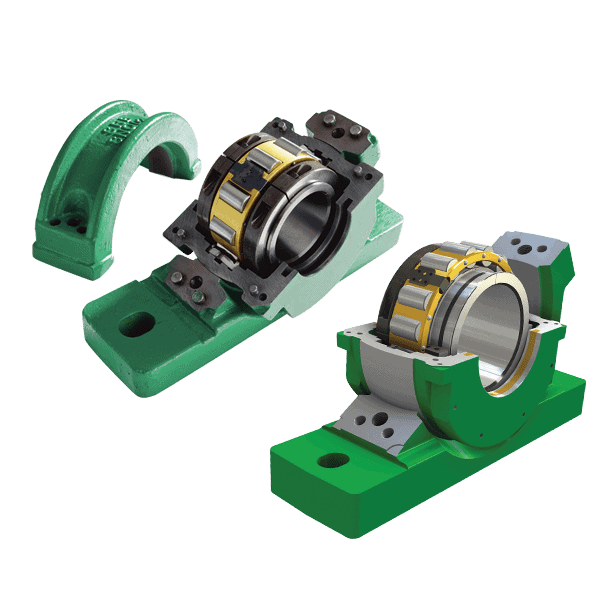

The Solution

Enter Timken split cylindrical roller bearings and seals. The housed unit’s angular split eliminated the need to remove the drive, the shaft is simply supported by a jack while the split housed unit is mounted around the shaft – adding tremendous value by eliminating the need for a crane hire and the time usually spent moving equipment to change out a standard roller bearing. The customer also was pleased with the quick response and service of Timken service engineers, as well as the fact that Timken had the re