Applying Technology

Ultra-Quiet Bearings, Ultra-Efficient Design: Partnering with Customers on NVH

Victor Li, senior NVH engineering specialist

Everyone knows: A quiet bearing is a quality bearing. The more snugly a bearing fits in its housing, the more balanced and undetectable its movements, the more likely it will be to last for years.

Over the past decade, original equipment manufacturers (OEMs) have increasingly added sound requirements to their bearing specifications for general industrial applications.

“In many cases, customers are concerned about noise-causing vibration that could lead to performance challenges in the larger system,” says Victor Li, Timken’s senior NVH engineering specialist. In other cases, he says, new government regulations play a role, protecting the hearing of operators working around heavy equipment, or reducing noise pollution for residential communities.

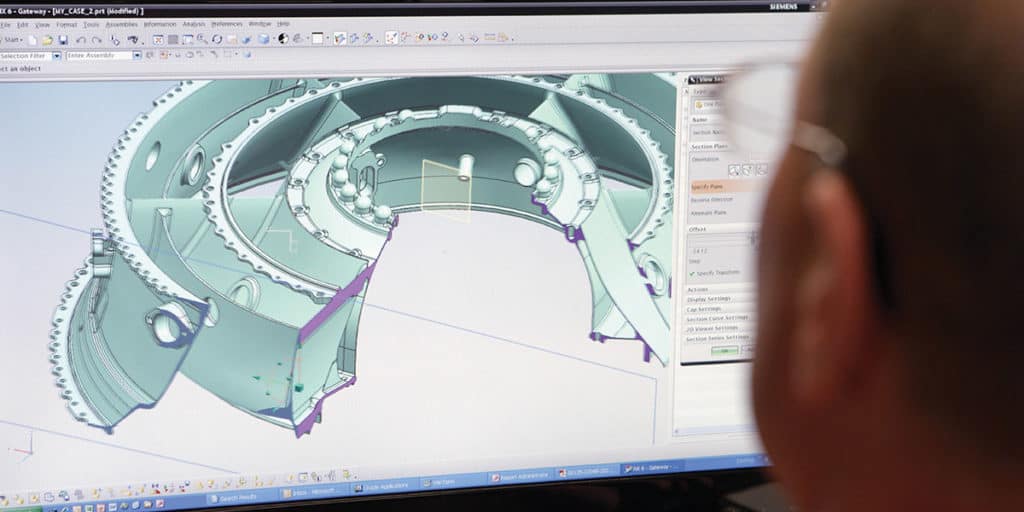

To help address strict noise, vibrations and harshness (NVH) requirements while reducing costs over the life of a bearing, Timken R&D continues to make significant investments in the field. When Li joined Timken in 2012, he began working on software tools that Timken engineers could use to simulate noise and vibration early in the design process, to help make the process for designing low-NVH bearings more efficient and precise.

Developing Timken’s NVH simulation software

A quiet bearing is a quality bearing—but what’s the difference between a bearing that vibrates and makes noise and one that doesn’t? Praveen Pauskar, group leader and technologist at Timken, explains that when you look beyond what the naked eye can see, you realize there’s no such thing as a perfectly flat or smooth surface. Everything is subject to a certain amount of variation during the manufacturing process.

“There’s undulation, waviness on the surface, along with some roughness,” he says. “Timken engineers can control the amount of undulation or roughness, but in general, the greater the precision, the more expensive the manufacturing process.”

The challenge, then, is to design bearings that meet performance requirements while also staying within reasonable manufacturing parameters. Without simulation software, engineers are forced to go through a repetitive process of designing bearings, making the physical parts, putting them on a test rig, and measuring the NVH.

After conducting some customer research, Li began measuring bearing noise and vibration in the sound test lab, using the data as input to design computer modeling software that designers could use to find the NVH performance “sweet spot” more quickly and accurately. He started with a dynamic, time domain-based modeling tool that worked well but sometimes took two days for a single simulation.

To speed up analysis, Li went on to develop a frequency domain-based model—what is now Timken’s Virtual Sound Test System (VSTS).

Shorter lead times. More precise, high-quality bearings.

After a year of successful tests, the team began using VSTS with customers. They started with a manufacturer whose design team had requested strict specifications for every bearing component—from the inner and outer rings to the individual rollers.

Together, the Timken sales and custom engineering teams worked with R&D to run VSTS simulations for the scenarios that the customer was designing for. They presented the resulting data as proof that Timken’s proposed alternative bearing would have the same or better performance than the one the customer had requested.

Predicting NVH at the system level

As a concurrent engineering tool, VSTS allows Timken engineers to work with OEM designers at the earliest stages of product development. “We can simulate all of the design features of a bearing,” says Li, “rotating it at different speeds or under different load conditions. We can simulate how the outer and inner rings are rotating, and the typical working conditions of the use case.”

When you combine all of the VSTS input data together, says Li, you can simulate noise and vibration for entire systems, rather than just one bearing. Predicting NVH at the system level makes it easy to work with OEM designers, who typically do not provide all the design details of their use case when requesting bearings.

“The first step is always to validate the VSTS model for the customer,” says Li, “to show them how well the simulation matches up with reality.” To do that, he creates a tiny dent on a ring surface or roller body. Then, he measures the dent in the metrology lab and uses it as an input for the model that predicts the vibration. Finally, he uses sophisticated sound test equipment in the R&D laboratories to validate the VSTS results

Partnering with customers to solve for NVH

Timken’s most recent sound test equipment additions expand the company’s capability to test larger bearings up to 24-inch (60.96 centimeters) O.D. (outside diameter) in tapered, cylindrical, spherical as well as ball bearings. “We are developing a suite of advanced NVH capabilities,” says Ryan Evans, Timken’s director of research and development (R&D).

“The NVH diagnostic equipment is like an EKG for machines,” he says. With it, Li can analyze sound on-site or through an audio recording, to measure NVH performance and identify where sounds are coming from. “With Victor’s expertise and these tools, Timken offers customers a unique way to address NVH issues, whether or not they are specifically bearing-related problems,” says Evans.

“At Timken, we’re interested in helping customers in the field with sound analysis and in the office with VSTS simulation,” he says. “We cover the whole range. As NVH rises in importance to customers, Timken looks forward to partnering with them to meet the challenges it poses for each industry we serve.”

Last Updated: 2020/07/21

Published: 2019/09/13