Rollon 7th Axis Solutions: Enabling Sophisticated Robots to ‘Walk’

Unlocking the Potential of the Seventh Axis

Across industries, robots complete tasks at levels of speed, accuracy, and efficiency that help humans achieve more with less. Manufacturers continue pushing machine designers to build automated production lines that yield greater output and capital investment returns. In response, many designers are moving beyond the traditional six axes—forward, backward, up, down and side to side—toward a ‘seventh axis’ that essentially gives legs to previously stationary equipment.

Rollon is a leader in linear motion and part of The Timken Company’s broad portfolio of power transmission and motion control solutions. As a top provider of linear motion solutions throughout Europe, Italy-based Rollon is rapidly becoming an authoritative design influencer in the global factory automation market.

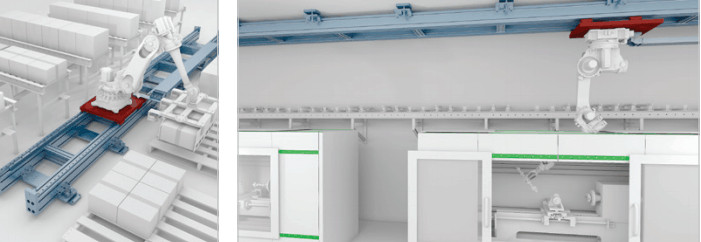

Through its expertise in designing and manufacturing seventh axis system solutions, Rollon helps machine builders increase the freedom of maneuverability in robotic arms across a variety of applications. Watch the system in action:

“Current Six Axis systems utilize robots that are permanently fixed at a single work station,” says Yuji Hayashi, Rollon’s Asia Pacific sales manager for actuator and systems. “Our mission with Seventh Axis systems is to design ways for these robots to ‘walk’ and be more productive. We provide machine designers with knowledge and products that are easily customized and integrated into their own system designs. For the manufacturers that operate these automated lines, our technology can help take their productivity, accuracy, and workplace safety to new heights while helping them get their products to market faster.”

Seventh Axis Shuttle System at Work

A single robot can do the work of several by moving over long distances—and between multiple work stations—via an integrated actuator system line operating on the seventh axis. The foundation includes a set of rails, adjustable steel crosspieces, and feet that mount the system in place. Adapter plates allow robotic arms to be mounted securely to the crosspieces. Highly-engineered rack and rail lubrication systems support the potentially infinite loops of each robot.

Each system is powered by custom-selected gearboxes. The “brains” of the operation come in the form of features like proximity switches and anti-collision system options. The design’s versatility also allows for floor-, ceiling-, or wall-mounting depending on requirements.

“We’ve applied 40+ years of experience in designing and producing linear motion products to create seventh axis systems in seven different sizes, with the capability to move any type of robot weighing up to 2000 kg (4,409 lbs.),” Yuji says. “Our offering and expertise allow machine builders to focus on what they do best and trust us with the linear motion aspects of their projects.”

The approach mirrors how engineers across all Timken product lines innovate for the future. “Timken and Rollon have very strong technical staff—solving problems through engineering, premium product manufacturing and outstanding service,” Yuji continues. “Our collective knowledge in power transmission and motion control means we can develop solutions to last at a very rapid pace.”

Customizing the Seventh Axis for Global Markets/Customers

Rollon Seventh Axis systems are suited for any precision manufacturing facility looking to increase the number of tasks a single robot can perform. They also can be integrated into existing six-axis robot systems in industries like machine tool automation, appliance and electronic manufacturing, and automotive production.

“We’ve helped consumer appliance producers in Italy shorten cycle times for high-demand consumer goods like dishwashers,” Yuji notes. In Japan, which ranks third in auto production and supplies 10 percent of the world’s vehicles[1], machine builders are interested in achieving the same results for their automotive customers.

Two recent Rollon Seventh Axis installations occurred at Japan-based automotive suppliers that manufacture transmissions and other drive train components. In one facility, Seventh Axis is integrated into long machining lines where robotic loading and unloading stands move heavy workpieces from one work machine to another. In a different facility, Seventh Axis technology helps robots move large sheets of metal into and out of a heat-treat operation – a job that is extremely dangerous for humans.

“While each global region, industry and customer has different philosophies and technologies, we are seeing that everyone is curious about the next wave of automation innovation,” Yuji says. “Seventh Axis is definitely a part of that future, and Rollon is ready to apply our technologies to solving customer challenges, whatever and wherever they are.”

The next wave of automation innovation is here.

Published: 2020/12/14