Growth

Adding Linear Motion to the Customer Toolkit

Skilled labor markets are tightening around the world as populations age and economies expand. The automation market promises to help manufacturers keep production strong, while supplying goods to meet growing global demand.

For Timken, it was a good time to make a strong move into robotics and automation, and The Rollon Group was a nice fit. The company, headquartered in Italy and with major operations in Germany, the U.S., and China, has differentiated itself over its 43-year history with unmatched engineering expertise and highly customized linear motion solutions. Since 2010, Rollon has rapidly expanded its activity around the world.

Timken completed its acquisition of Rollon in 2018. “Rollon is unique in the linear motion space,” says Ajay Das, vice president, strategy & business development. “Its solutions are unmatched, technically and from a value proposition point of view. That model fits perfectly with Timken’s mission to be a solution provider and technical expert in the power transmission space.”

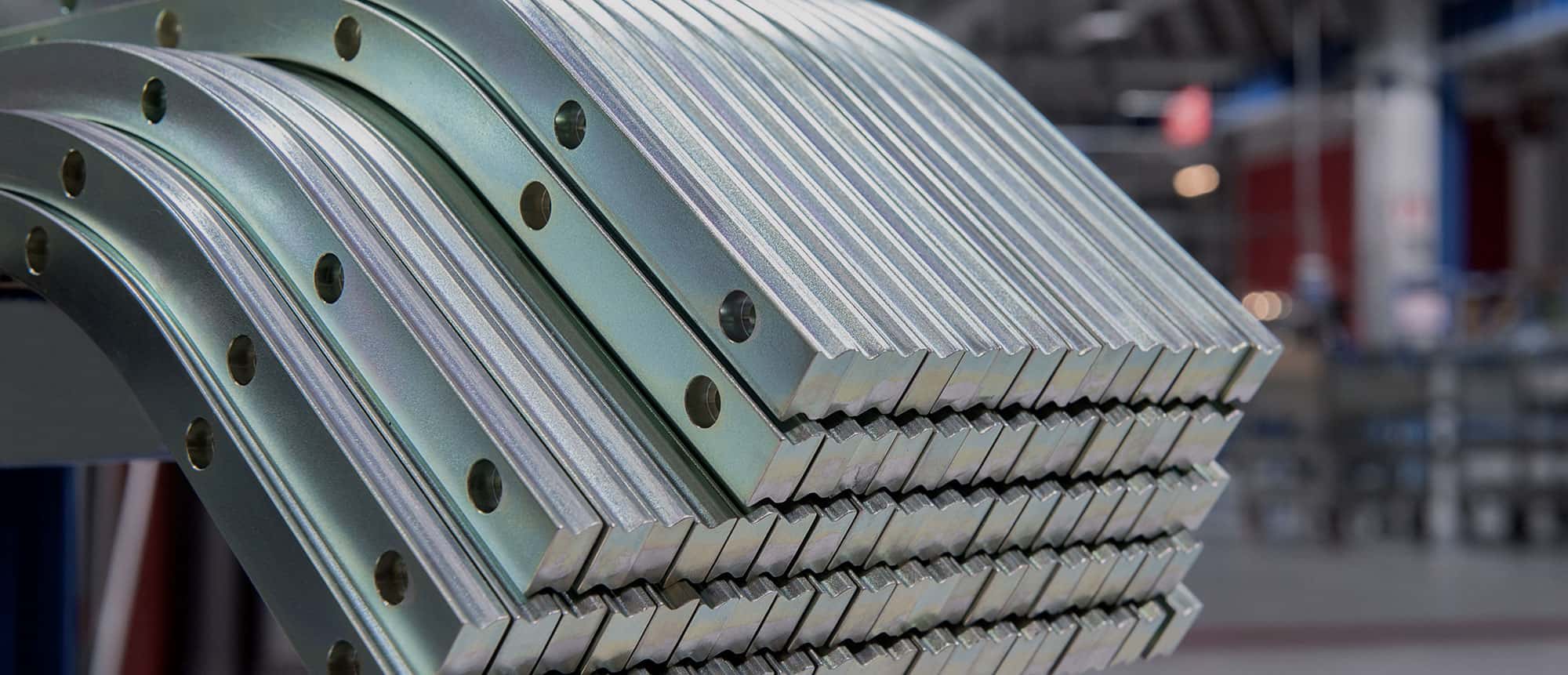

Rollon’s Seventh Axis product is a shuttle system that moves robots and heavy loads quickly and smoothly over long distances.

Rollon’s Seventh Axis product is a shuttle system that moves robots and heavy loads quickly and smoothly over long distances.

Opportunities for dialogue and collaboration

With Rollon under its umbrella, Timken makes strong inroads into robotics and light industrial markets, strengthens its presence in the rail and aerospace industries and expands its geographic footprint.

While Timken has always specialized in rotational motion, Rollon focuses its technical expertise on moving objects in a straight line. For example, Rollon telescopic rails allow airline or rail passenger seats to stretch out, for greater adjustability and comfort. The company plays an essential role in automated factories, where machines move materials up the production line, doors and drawers open and close, and robots change tools by sliding up, down, and sideways — faster and with more precision and versatility than ever before.

Of course, moving rails smoothly in a line also requires a degree of rotational motion, in the form of precision ball bearings that can handle high load capacities. “We see opportunities for Rollon to leverage Timken’s product offerings and technical expertise in couplings and bearings to further enhance current and future Rollon product lines,” says Das. “That collaboration could offer customer advantages in terms of both performance and cost.”

While Rollon will move forward under its current brand with its own dedicated sales force, the two teams have been charged with building a strong partnership. “I expect positive and frequent discussion, dialogue and collaboration between the different sales groups,” he says.

Complementary geographies

Geographically, the two companies complement each other well. With Timken’s established brand strength and extensive infrastructure in North America and Asia, Rollon will be able to expand into those areas faster than it could have as a standalone company.

“It’s going to be fantastic, what we can do,” says Das. For example, there’s a significant machine tool market in South Korea, but Rollon doesn’t have a current presence there. Figuring out labor laws can be a monumental task, but with Timken’s established infrastructure, he expects to get a Rollon offering up and running in South Korea very quickly.

At the same time, Rollon offers inroads into strong European markets. Take, for instance, passenger rail. Rollon provides components for doors, seats, tables, and other passenger car applications that require movement or adjustment. Timken is strong in U.S. industrial rail markets and a leading supplier of the journal bearings that keep cars moving smoothly on the tracks. Merging the two companies could help manufacturers improve the quality and durability of rail components, and increase purchasing efficiency.

Rollon supplies telescopic rails for passenger train doors.

Far-reaching customer benefits

The Rollon acquisition offers Timken customers the advantage of a wider range of engineering expertise and solutions. “We’re more of a one-stop shop than ever,” says Das. “Customers now have access to our decades of experience not only with tapered roller bearings, industrial bearings, chains, belts, couplings and other power transmission problems — but also now, linear motion solutions.”

Das expects the combined knowledge and experience of both companies to boost product innovation for customers across the board in the coming years. “Rollon comes with expertise in areas of induction heat treatment and assembly,” he says. “They deal with aluminum and material profiles that we don’t have experience with yet at Timken.”

Rollon customers, on the other hand, gain access to Timken’s 120 years of experience and knowledge in broad areas, such as materials science and manufacturing processes. Those intellectual assets, combined with Timken’s infrastructure and distribution network, offer opportunities to scale solutions up and replicate them around the world.

Building on premium solutions

As Timken has grown into a diversified industrial company, its leaders understand the importance of maintaining the reputation of premium quality and service that the company was built on.

“Many of our bearing customers come to us because of our engineering knowledge,” says Das. Timken helps customers identify the best solutions, so they can minimize testing and validation and get products to market faster.

While Timken’s venture into linear motion is new, the Rollon purchase makes perfect sense from that business model perspective.

“The Timken Company is all about solving customer’s problems,” says Das. “Rollon fits that theme exactly. They solve technical problems through engineering. It’s a logical expansion, for Timken.”

Hear more about how the Timken acquisition strategy makes the company better, not just bigger.

Last Updated: 2024/04/29

Published: 2023/03/27