Expertise

A Century of Aerospace Innovation

Aerospace engineers have turned to Timken for friction reduction solutions for as long as there have been airplanes, helicopters, spaceships, and satellites. Any machine designed to take flight needs strong, efficient bearings that can withstand extreme conditions and perform reliably in critical situations.

Today, Timken engineers are collaborating with aerospace partners all over the world to imagine, develop, and produce the flying machines of the 21st century. They’re designing next-generation helicopters that are more efficient; working with NASA on Dragonfly, the rotorcraft that will explore Saturn’s moon of Titan; and fine-tuning the electric-vertical takeoff and landing taxis that will transform cities.

From the Wright Flyer to the Webb Telescope, see how Timken teams have helped solve critical aerospace challenges over the decades.

- 1903

- 1930s

- Mid-1930s

- 1935

- 1940s

- 1953

- 1964

- 1969

- 1996

- 2003

- 2009

- 2012

- 2020

- Feb. 2021

- Dec. 2021

- 2023

- Oct. 2024

-

Earthbound No More

Using Diamond® chain products from their bicycle shop, Orville & Wilbur Wright pioneer the era of aviation with the world’s first manned, controlled flight near Kitty Hawk, North Carolina.

-

Ubiquitous Durability

Timken is the go-to supplier as the World War II Allies look for robust, rugged, durable bearing solutions. Each B-17 Flying Fortress uses 240 Timken bearings.

-

Super Steel Changes the Game

Timken metallurgist Martin Fleischmann patents a corrosion-resistant steel alloy which leads to Super Steel 16-25-6 — an alloy giving Allied bombers and fighter planes critical advantages in the final stages of World War II. Super Steel is also essential in the development of postwar turbojet engines.

-

A Revolution in Commercial Air Travel

Timken® bearings in the Douglas DC-3 make commercial air travel comfortable, reliable and profitable.

-

Bringing a Lifesaving Dream to Life

Timken engineers work closely with Igor Sikorsky to develop the R-4 — the first helicopter to be sold in high volume. Its ability to hover as well as fly up, down and sideways make it ideal for lifesaving missions.

-

Air Travel Upgrade

Twenty Timken® bearings — used in both the propellers and landing wheels — support the British Vickers Viscount, the first turboprop airliner — known for its smooth, quiet ride, panoramic windows and low operational costs.

-

Mach 3 Speeds

Longtime partner, B.F. Goodrich designs Timken® bearing into the landing gear of the Lockheed SR-71 Blackbird US Air Force reconnaissance plane. Built to fly above Mach 3 (three times the speed of sound), its 1976 airspeed record for air-breathing flight — 2,193.2 mph — still stands.

-

Guiding the First Moon Walkers

Timken’s work on inertial guidance systems bears fruit in Apollo 11’s Lunar Exploration Module, guiding astronauts to the moon for the first time. The same system is used in 1970’s Apollo 13 to guide astronauts back to Earth after the main guidance system fails.

-

Exploring Mars: Pathfinder

Timken® miniature, precision bearings play a critical role in the Pathfinder mission, which lands Sojourner, the first rover to explore the Red Planet.

-

Exploring Mars: Spirit and Opportunity

NASA’s “twin robot geologists,” Spirit and Opportunity rovers, rely on Timken bearings for their descent to Mars.

-

Meeting the Extreme Challenges of Space

Astronauts embark on a spacewalk to make delicate repairs to the 30-year-old Hubble Space Telescope. To withstand the extreme operating temps and vacuum of space, the mini power tools they carry use a custom thin-section precision ball bearing designed by Timken engineers.

-

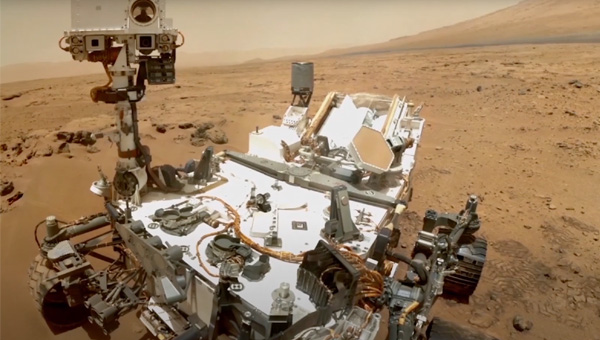

Exploring Mars: Curiosity

In addition to using Timken® bearings in its descent, the Curiosity rover also has Timken® bearings in the center hub of its sample carousel system. Two ¼ inch (6.35 mm) Timken® bearings also run the tiny vacuum pump that supports the rover’s analytical equipment.

-

Covid-19 Disrupts Air Travel

When thousands of passenger jets are grounded during the Covid-19 pandemic, the all-important landing wheel bearings sit quiet — a state they were never designed for — Timken service engineers step in to develop maintenance and inspection procedures so aircraft can return to service quickly and safely when the time comes.

-

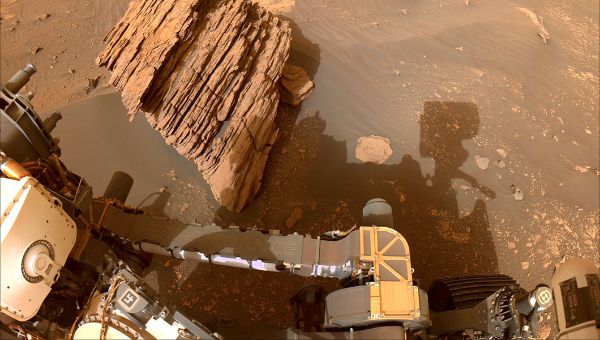

Exploring Mars: Perseverance

GGB, a Timken brand, partners with NASA to develop tribological solutions used in the sampling and caching systems of the Perseverance Rover which lands on Mars in search of signs of ancient life.

-

Peering Into Infinity

Supported with Timken technology, The James Webb Space Telescope launches a new era of deep space exploration. Timken bearings are used in two critical systems: Mechanisms that secure key components of the space telescope prior to deployment, and the downlink antenna that makes communication possible.

-

Next-Level Efficiency

Timken launches a complete line of tapered and cylindrical bearings featuring silicon nitride (ceramic) rollers. The hybrid bearings are lighter, stronger, and more efficient than all-steel bearings — perfect for extreme aerospace requirements.

-

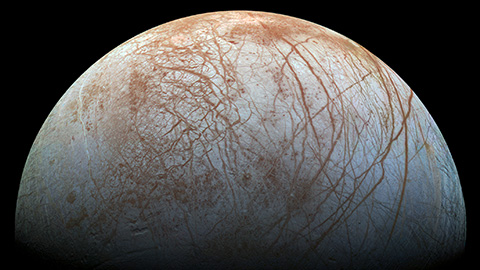

NASA launches Europa Clipper

NASA recently launched the Europa Clipper, a robotic, solar-powered spacecraft built to orbit Jupiter and capture high-resolution images of Europa, one of its four largest moons. Scientists will use the images to understand Europa’s icy shell, determine if the ocean beneath it could support life and identify sites for future landing missions.

High-precision, preloaded stainless thin-section bearing pairs from Timken support the camera system mounted on the outside of the spacecraft — with minimal protection from the temperature and radiation extremes it will encounter on its multi-year flight.

“Most of the world’s aircraft take off and land on Timken landing wheel bearings. Billions of lives every year rely on that critical part, which has to withstand extreme conditions multiple times a day.”

PAUL EASON

AEROSPACE ENGINEER

“Customers trust our bearing expertise to help them explore space, make discoveries about the universe and even track and predict weather.”

SCOTT LAFALAM

APPLICATION ENGINEERING SPECIALIST

“Timken’s wear-resistant, thermally managed, high-speed, power-dense, high-load products fit right into what aircraft designers are looking for.”

DR. RYAN EVANS

DIRECTOR, RESEARCH & DEVELOPMENT

As we move into the future, one thing is clear: Aerospace breakthroughs will always be community efforts — bringing people together across cultures and space to learn from each other and make the most difficult challenges look easy.

Learn about the technologies that give Timken customers a head start on the friction-reduction problems inherent to electric flight.

Last Updated: 2023/05/02

Published: 2023/05/02